netzsch

Pompen & Systemen

Uw voordelen met NETZSCH Pompen & Systemen

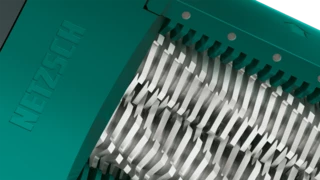

Als wereldwijde specialist in complexe vloeistofbehandeling is klanttevredenheid onze hoogste prioriteit. NETZSCH ontwikkelt, produceert en distribueert wereldwijd al meer dan 70 jaar verdringerpompen.

Wij bieden op maat gemaakte pompoplossingen die voldoen aan uw specificaties. Daarbij beloven wij u Bewezen Uitmuntendheid - uitstekende prestaties op alle gebieden. Zelfs complexe media vormen geen probleem voor ons brede productassortiment.

75000

210

70

Proven Excellence

NETZSCH Pumps & Systems world

Navigeer door de intuïtieve wereld van NETZSCH en ontdek de juiste oplossing voor uw toepassing.

NETZSCH Pumps & Systems-toepassingen

Of het nu gaat om milieu & energie, chemie, pulp & papier, voeding & farmacie, mijnbouw, olie & gas upstream, mid- / downstream of batterijen: bij NETZSCH ontwikkelen we de juiste pompoplossing voor uw individuele eisen.